Products

Useful Links

- Choose professional Small Sunflower Seed Oil Refinery Line

- Professionally Designed Mini Oil Mill for Home Use

- Is Small Oil Production Line Worth for Investment?

- How to Build Small Edible Oil Production Line?

- Small Oil Mill Plant for Daily Requirement

- Small Edible Oil Refinery Plant Cost Can Be Reduced Relatively

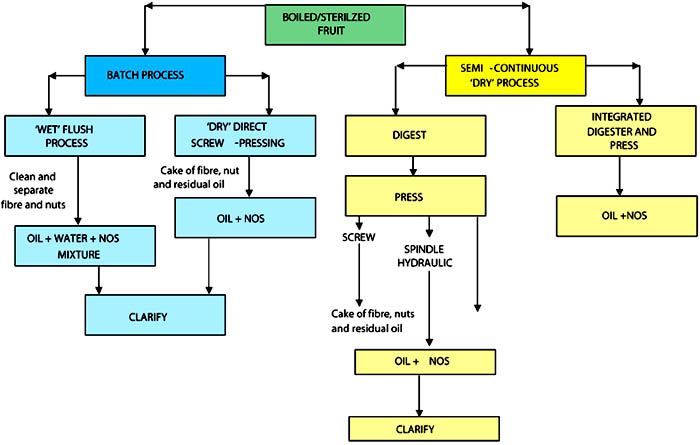

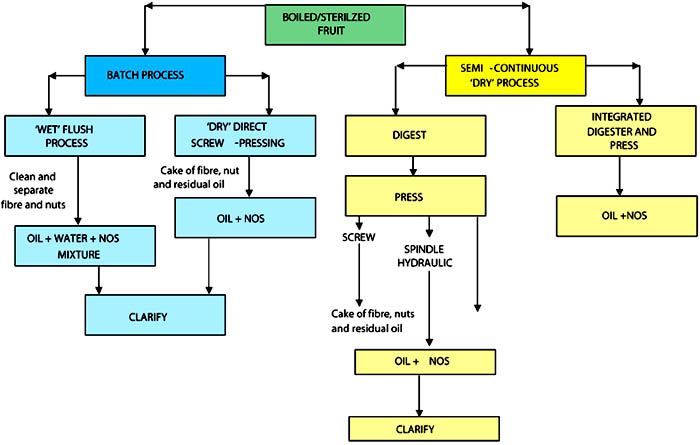

- How to Extract Palm Oil from Palm Fruit-Oil Mill Plant

- start oil extraction factory

Latest News

Apr 10, 2018

Mar 30, 2018

palm oil manufacturing process

Home > Useful Links >

Obtained from the fruit (both the flesh and the kernel) of the oil palm tree, it contributes to the economic development of the producing countries and to the diets of millions of people around the world. Oil palms can grow 20 metres tall with leaves up to 5 metres long. They bear clusters of fruit all year long, with each fully matured cluster weighing up to 50kg.Oil palms are highly efficient oil producers, with each fruit containing about 50% oil. As a result they require ten times less land than other oil-producing crops. Palm oil and palm kernel oil are entirely GM free. Vegetable oil production around the world totals over 144 million tons per year, of which over 47 million tones is palm oil. Along with soy oil, palm oil makes up 60% of world production.

At the first stage palm are pressed into crude palm oil. Then it is processed into liquid palm olein (80%) and solid palm stearin (20%). These might then be blended with other oils, or undergo further processes such as interesterification, to create new oils with different physical and chemical characteristics. These are used as ingredients within shortenings, margarines for pastry and cakes, frying oils, coffee whitener and emulsifiers.

We provide all the palm oil manufacturing process plant whcih included, palm oil pressing plant, palm oil solvent extraction plant and palm oil refinery plant. We can supply semi-continuous palm oil pressing equipment for and continuity sets of oil equipment. By the customers requirement we can provide all the palm oil manufacturing process lines. Any part of this edible oil manufacturing line can be provided by us. We also sell part of them and whole line of the plam oil prodcution line.

Advantages of Palm Oil Manufacturing Process Plant

Palm Oil Pressing Plant and Solvent Extraction Plant

Our palm oil manufacturing process machine is suitable for pressing all kinds of palms for edible use. And then it will be further processed into solvent extraction stage. By using chemical solvent to dissolve oil content contained in cake or the palms. Oil is collected by vaporizing solvent out which is later recycled.

Palm Oil Refinery Plant

In configuring the palm oil solvent extraction plant, pre-pressing may be involved in which case seeds are lightly pressed leaving about 14% to 18% oil in pressed cake. Solvent extraction section of palm oil manufacturing process will further process these cakes and leave only 2% oil in the final cake (meal). This method results in higher capacity; Lower power consumption, lower wear & tear / maintenance and high extract efficiency. Thus it could be used as complement equipment to extract the oil remained in cake, which gives extra profit to entrepreneurs. Or the solvent extraction could be configured to process raw soybean and some other seeds directly.

Contact us now to get support on our palm oil manufacturing process for your palm oil mill today and double your oil output tomorrow.

At the first stage palm are pressed into crude palm oil. Then it is processed into liquid palm olein (80%) and solid palm stearin (20%). These might then be blended with other oils, or undergo further processes such as interesterification, to create new oils with different physical and chemical characteristics. These are used as ingredients within shortenings, margarines for pastry and cakes, frying oils, coffee whitener and emulsifiers.

We provide all the palm oil manufacturing process plant whcih included, palm oil pressing plant, palm oil solvent extraction plant and palm oil refinery plant. We can supply semi-continuous palm oil pressing equipment for and continuity sets of oil equipment. By the customers requirement we can provide all the palm oil manufacturing process lines. Any part of this edible oil manufacturing line can be provided by us. We also sell part of them and whole line of the plam oil prodcution line.

Advantages of Palm Oil Manufacturing Process Plant

- Multipurpose palm oil manufacturing process machine.

- Advanced palm oil manufacturing process is applied in our machine.

- Low oil retention in oil meals.

- Low solvent consumption.

- High output and excellent in quality.

- Competitive in price and service.

Palm Oil Pressing Line

Palm Oil Pressing Plant and Solvent Extraction Plant

Our palm oil manufacturing process machine is suitable for pressing all kinds of palms for edible use. And then it will be further processed into solvent extraction stage. By using chemical solvent to dissolve oil content contained in cake or the palms. Oil is collected by vaporizing solvent out which is later recycled.

Palm Oil Refinery Plant

In configuring the palm oil solvent extraction plant, pre-pressing may be involved in which case seeds are lightly pressed leaving about 14% to 18% oil in pressed cake. Solvent extraction section of palm oil manufacturing process will further process these cakes and leave only 2% oil in the final cake (meal). This method results in higher capacity; Lower power consumption, lower wear & tear / maintenance and high extract efficiency. Thus it could be used as complement equipment to extract the oil remained in cake, which gives extra profit to entrepreneurs. Or the solvent extraction could be configured to process raw soybean and some other seeds directly.

Palm Oil Solvent Extraction Line

Contact us now to get support on our palm oil manufacturing process for your palm oil mill today and double your oil output tomorrow.

Henan Kingman M&E Complete Plant Co., Ltd ©

Email:info@oilmillplant.com

Français

Français Русский

Русский Español

Español