Products

Useful Links

- Choose professional Small Sunflower Seed Oil Refinery Line

- Professionally Designed Mini Oil Mill for Home Use

- Is Small Oil Production Line Worth for Investment?

- How to Build Small Edible Oil Production Line?

- Small Oil Mill Plant for Daily Requirement

- Small Edible Oil Refinery Plant Cost Can Be Reduced Relatively

- How to Extract Palm Oil from Palm Fruit-Oil Mill Plant

- start oil extraction factory

Latest News

Apr 10, 2018

Mar 30, 2018

palm oil refinery plant

Home > Useful Links >

In order to get top qualifity palm oil, palm oil refinery plant is necessary in every palm oil mill.KMEC is a professional supplier of palm oil refinery plant in China. We offer the best palm oil extraction machine and palm oil refinery plant for both large scale and small scale oil mill with the most competitive price to the customer all over the world. Join us and have your own palm oil refinery plant and make big money.

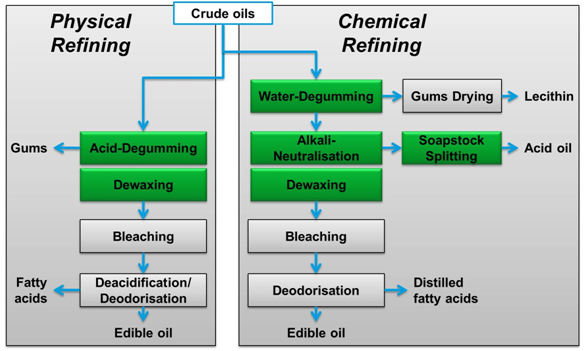

There are several ways to extract palm oil from palm kernels. Mechanical extraction processes are suitable for both small and large scale operations. The three basic steps in palm oil refinery processing plant, namely degumming, bleaching and deodorising.

After pressing process, there are many impurities in the crude palm oil, which might have bad influence on the oil’s sensory and edible qualities. Therefore, it is necessary to refine the crude oil.In another word, without oil refinery , the crude oil is not edible for human being.

Considering the need of palm oil refinery plant and the customs' requirement, we selects best technology and superior palm oil refinery machine fabrication and automatic control system, which provides perfect technique and service to satisfy the customs' refining requirement and to create first-class refining process with our professional palm kernel refinery machinery .

The Refinery Processing of Palm Oil Refinery

In degumming, the gum and fatty acid in crude palm oil and crude palm kernel oil are separated together with other impurities such as trace minerals, copper and iron by the application of phosphoric acid.

In bleaching, the oil is mixed with bleaching earth (bentonite calcium) in a vacuum room to remove impurities and colour pigments in the palm oil. In deodorising, the odour and taste of the oil is removed when the oil is steamed at high temperatures between 240°C to 260°C and then cooled to room temperature.

RBD palm stearin and RBD palm olein are obtained by the fractionation of RBD palm oil; whereas RBD palm kernel stearin and RBD palm kernel olein are obtained by the fractionation of RBD palm kernel oil. Through a process known as crystallisation, RBD oil is cooled until crystals are formed.

The crystallized oil in the crystallizer is then filtered through a membrane to separate the liquid fraction i.e. olein from the solid fraction i.e. stearin. RBD palm olein is usually sold as cooking oil and may go through further fractionation depending on the quality required.

Contact us to get more information if you are interested in our palm oil refinery plant. We are always ready to serve you.

There are several ways to extract palm oil from palm kernels. Mechanical extraction processes are suitable for both small and large scale operations. The three basic steps in palm oil refinery processing plant, namely degumming, bleaching and deodorising.

Process of refining crude palm oil

After pressing process, there are many impurities in the crude palm oil, which might have bad influence on the oil’s sensory and edible qualities. Therefore, it is necessary to refine the crude oil.In another word, without oil refinery , the crude oil is not edible for human being.

Considering the need of palm oil refinery plant and the customs' requirement, we selects best technology and superior palm oil refinery machine fabrication and automatic control system, which provides perfect technique and service to satisfy the customs' refining requirement and to create first-class refining process with our professional palm kernel refinery machinery .

The Refinery Processing of Palm Oil Refinery

In degumming, the gum and fatty acid in crude palm oil and crude palm kernel oil are separated together with other impurities such as trace minerals, copper and iron by the application of phosphoric acid.

In bleaching, the oil is mixed with bleaching earth (bentonite calcium) in a vacuum room to remove impurities and colour pigments in the palm oil. In deodorising, the odour and taste of the oil is removed when the oil is steamed at high temperatures between 240°C to 260°C and then cooled to room temperature.

RBD palm stearin and RBD palm olein are obtained by the fractionation of RBD palm oil; whereas RBD palm kernel stearin and RBD palm kernel olein are obtained by the fractionation of RBD palm kernel oil. Through a process known as crystallisation, RBD oil is cooled until crystals are formed.

The crystallized oil in the crystallizer is then filtered through a membrane to separate the liquid fraction i.e. olein from the solid fraction i.e. stearin. RBD palm olein is usually sold as cooking oil and may go through further fractionation depending on the quality required.

Contact us to get more information if you are interested in our palm oil refinery plant. We are always ready to serve you.

Henan Kingman M&E Complete Plant Co., Ltd ©

Email:info@oilmillplant.com

Français

Français Русский

Русский Español

Español